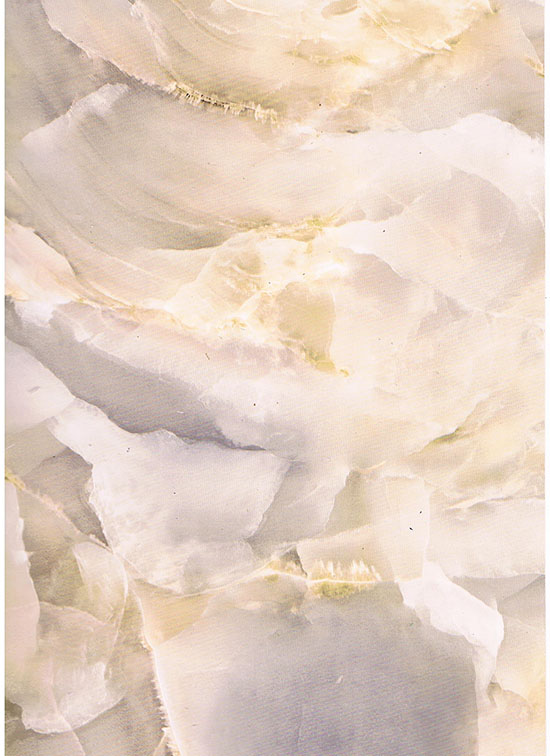

晶钙板系列

晶钙板:

模拟天然岩积物融合冲积的肌理效果,精造层次繁复、变化多元的细密线条,

如大气写意的艺术笔触,由浅入深,深浅交错.使纹理更自然丰润,板面更立体通透;

所及之处光色舒缓流畅、深沉富蕴。张扬地随思随想,拼凑着更丰富的视觉组合;

这是一个自由发挥自主装饰风格的天堂,驰骋个性和想象。

组成:

由底面涂覆一道防水UV清漆,表面真空压印仿天然大理石图案和UV氟碳清漆组成。

特性:

具有天然大理石的效果,纹路清晰,颜色均匀,避免了大面积装饰时天然太理石的色差,表面光滑,耐磨,硬度高可达

5H一6H,易清洁,耐污染,A级防火,无辐射,质量轻,重量是天然石的l/5,价格是天然石的1/10。

用途:

代替天然大理石,用于建筑内外墙装饰,如酒店、写字楼、商场、机场、地铁站、办公室、电视背景墙、卫生间、厨房等。

CALCIUM CRYSTAL PLATE SERIES

The effect is simulate natural marble and alluvial deposit fusion skin texture.

levels complexity,close grain is changing and complex,such asmagnificent brushwork,

fromthe shallower to the deeper.alternating color,make the texture full and natural,

the surface more stereoscopic and transparent. The light color is comferable andfluency.

piece together with a rich visual combination This is a world which can be free played

and decide decoration style with independent.

ComPosition:First coated with UV varnish,then embossed marbleizing with vacuum,

final coated with UV fluorocarbon lacquer.

Feature:With natural marble effect,fexture clear,uniform color,avoid the color

dlfference when decorate large area,smooth surface,high hardness can be upto 5H一6H easytoclean

exeellent stain resistance,A—classfire Protection,non—radiative,light weight,the weight is about

one—fifth of natural marble,1he price is about one—tenth of natural marble

ApPlication:Replacethe naturalmarble,apply to interior & exterior decoration like hotel,

office,TV wall.kitchen,restroom,office building,market airport subway station etc.

Installation&Construction

安装施工

实用便捷一晶钙板基材安装设计说明

Practical And Simple-installation And Design

Instructions for the Calcium crystal plate.

晶钙板基材基板为无机材料,表面已作涂装处理,它与铝塑板、石材一样安装完毕即可直接使用。

晶钙板基材热膨胀系数极小,所以板与板可以采用较小接缝的处理方式,以形成细小美观的装饰线。

无机材质导致卡利板材在切割加工过程中可能会产生少量崩边现象,当大量使用非标尺寸时,建议

由浙江新瑞铭装饰材料有限公司在制造基地先进行倒角定尺处理,然后再进行表面涂装,以达到边缘

美观的目的。在现场切割时,可用砂纸等打磨工具修边、倒角。

晶钙板基材在与金属龙骨接触的部位必须垫上弹性垫,如双面胶,使晶钙板基材与金属龙骨不是刚性接触。

The base board of the Calcium crystal plate is of inorganic material,whose surface

has undergone coating treatment.Like aluminum—plastic Panels and stone materials,

it can be putto use right after installation is completed.The thermal expansion

coefficien of the Calcium crystal plate is very small,SO the treatment method for

relatively small joints between the Panels can be adopeted so as to form thin and

beautiful decoration lines The inorganic MOC may cause the Calcium crystal plate

to produces mall amounts of edge cracks during the cutting process.When large

quantities of non—standard sizes are to be adopted,it iS recommended that chamfer and

size-fixing treatment be conducted by Jiangsu Shuang liang Composite Material Co., Ltd.

at the manufacturing base before surface coating is performed to achieve the purpose of

making the edge pleasing to the eye.At the time of field cutting,grinding tools such as

abrasive paper may be used for trimming and chamfer treatment.Elastic pads such as adhesive

tapes with glue on both sides must be used where the Calcium crystal plate touches the metal

keel so as to avoid hard touch between them.

Saving time and labor-processing of the Calcium crystal plate

省时省工-晶钙板基材的加工

晶钙板基材可采用一般气动或电动工具进行铣孔、切割等加工,切割刀具宜选密齿型或无齿型。

晶钙板基材可采用专用的钻铣刀进行钻孔开槽、倒角等。晶钙板基材所有因加工所露出的

基板均可用封闭漆进行封闭处理。

The Calcium crystal plate may be processed with ordinary pneumatic or electric

tools for milling holes or cutting.A cutting tool that features dense teeth

or no teeth had better be adopted.

special drilling and milling cutters may be adopted for drilling holes.

grooving,chamfer treatment,ect.for the Calcium crystal plate.Any part of the base Panel of

the Calcium crystal plate exposed due to processing may be enclosed with enclosing paint.